Product Overview

Customizable industrial liquid oxygen tanks

As a professional cryogenic storage solution tailored for industrial applications, our customizable industrial liquid oxygen tanks are designed to meet the diverse storage requirements in the fields of metallurgy, chemical engineering, medical oxygen supply and aerospace. Flexible customization options, strictly in compliance with international and domestic standards, provide reliable, safe and efficient liquid oxygen (LOX) storage performance for enterprises of all sizes.

1. Flexible customization options to meet your exact needs

We understand that different industrial scenarios have unique requirements for liquid oxygen storage capacity, size and accessory configuration. Our customizable industrial liquid oxygen tanks offer the following personalized options:

Capacity customization: From small 5m³ storage tanks used in laboratories and small workshops to large 200m³+ storage tanks used in large industrial production lines, it fully ADAPTS to on-site space and storage requirements.

Material customization: According to your requirements for corrosion resistance, pressure resistance and temperature resistance, choose high-quality carbon steel, 304/316L stainless steel or low alloy steel. All materials comply with the welding standards for pressure vessels, ensuring welding quality and structural stability.

Accessories customization: Equipped with customized pressure reducing valves, liquid level gauges, temperature monitoring systems, and conveying pipelines; Supports integration with automatic filling and automatic unloading systems to achieve intelligent warehouse management.

2. Strict safety and performance standards for low-temperature storage

Liquid oxygen storage requires ultra-low temperature and high-pressure sealing performance. Our products are designed with multiple safety guarantees:

Low-temperature adaptability: The tank body is processed with professional insulation technology, effectively maintaining the ultra-low-temperature environment required for liquid oxygen storage, reducing cold loss and lowering daily operating costs.

Pressure vessel compliance: All storage tanks are manufactured in accordance with ASME and GB150 standards and undergo strict pressure tests and leakage detection to prevent risks such as oxygen leakage and pressure accumulation.

Explosion-proof and anti-static design: The optimized structural design avoids the accumulation of static electricity and the risk of combustion caused by the evaporation of liquid oxygen, making it suitable for flammable and explosive industrial environments.

3. It is widely applicable to multiple industrial fields

Our customizable industrial liquid oxygen tanks are widely used in various high-demand scenarios

Metallurgical industry: Support oxygen-enriched combustion processes to enhance smelting efficiency and reduce energy consumption.

Chemical industry: As a raw material storage device for chemical synthesis reactions that require high-purity oxygen.

Medical and emergency supply: Provide stable liquid oxygen storage for hospitals, emergency centers, and oxygen plants.

Aerospace and electronics: Meeting the demand for high-purity oxygen in aerospace testing and electronic component manufacturing.

4. Professional after-sales support and long-term maintenance

We offer a full range of after-sales services to ensure the long-term stable operation of your equipment

The installation and commissioning are carried out on-site by professional technicians, and the layout of the storage tanks and the connection of pipelines are optimized in combination with the on-site conditions.

Regular maintenance guidance and component replacement services are provided to extend the service life of the storage tank.

24/7 technical consultation to promptly address your storage and operation issues.

Have any requirements for custom cryogenic liquid oxygen storage tanks? Contact us via our website, and our team will provide you with a tailored solution and detailed reply as soon as possible.

Specifications

| Cryogenic liquid Oxygen / Nitrogen /Argon /LNG Storage Tank | ||||

| NO. | Model | Dimension (mm) | Net Weight (KG) | Type |

| 1 | CFL-5/0.8 | Φ1916*5172 | 3930 | Vertical |

| 2 | CFL-10/0.8 | Φ2316*5981 | 5840 | |

| 3 | CFL-15/0.8 | Φ2316*8035 | 7900 | |

| 4 | CFL-20/0.8 | Φ2716*7377 | 9250 | |

| 5 | CFL-30/0.8 | Φ2920*8904 | 12600 | |

| 6 | CFL-40/0.8 | Φ2920*11290 | 16000 | |

| 7 | CFL-50/0.8 | Φ3220*11304 | 18700 | |

| 8 | CFL-80/0.8 | Φ3420*14920 | 31200 | |

| 9 | CFL-100/0.8 | Φ3420*18102 | 37200 | |

| 10 | CFL-150/0.8 | Φ3724*22128 | 53200 | |

| 11 | CFL-200/0.8 | Φ4024*24085 | 69400 | |

| 12 | CFL-50/1.6 | Φ3220*11304 | 25600 | |

| 13 | CFL-100/1.6 | Φ3520*17276 | 46300 | |

Company Profile

we measure our success by the success of our customers .

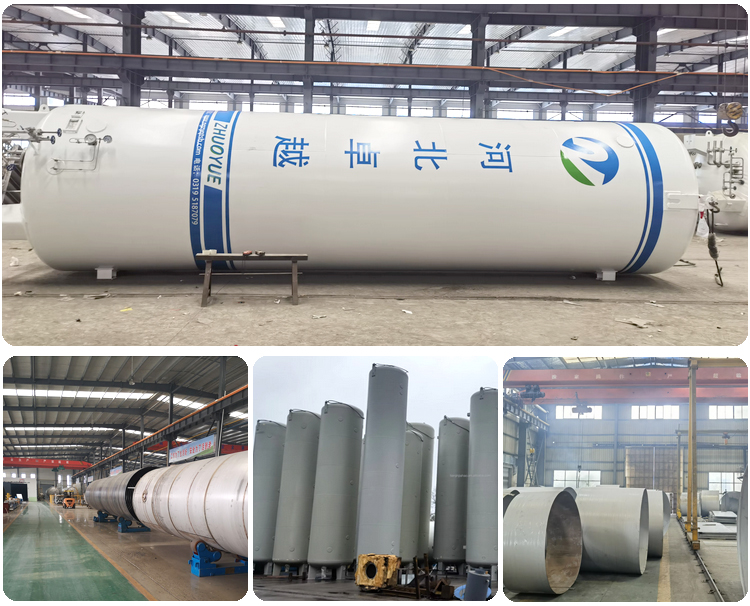

Production Workshop

Shipping & Packaging

Certifications