Specification

| Cryogenic liquid Oxygen / Nitrogen /Argon /LNG Storage Tank | ||||

| NO. | Model | Dimension (mm) | Net Weight (KG) | |

| 1 | CFL-5/0.8 | Φ1916*5172 | 3930 | Verical |

| 2 | CFL-10/0.8 | Φ2316*5981 | 5840 | |

| 3 | CFL-15/0.8 | Φ2316*8035 | 7900 | |

| 4 | CFL-20/0.8 | Φ2716*7377 | 9250 | |

| 5 | CFL-30/0.8 | Φ2920*8904 | 12600 | |

| 6 | CFL-40/0.8 | Φ2920*11290 | 16000 | |

| 7 | CFL-50/0.8 | Φ3220*11304 | 18700 | |

| 8 | CFL-80/0.8 | Φ3420*14920 | 31200 | |

| 9 | CFL-100/0.8 | Φ3420*18102 | 37200 | |

| 10 | CFL-150/0.8 | Φ3724*22128 | 53200 | |

| 11 | CFL-200/0.8 | Φ4024*24085 | 69400 | |

| 12 | CFL-50/1.6 | Φ3220*11304 | 25600 | |

| 13 | FL-100/1.6 | Φ3520*17276 | 46300 | |

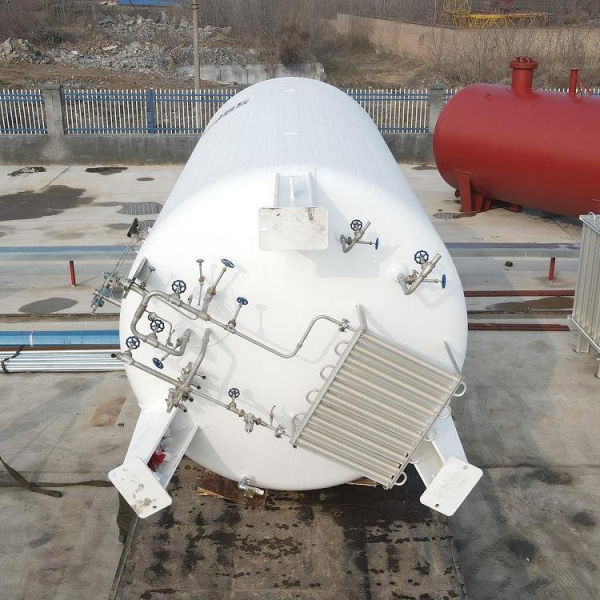

Product Introduction(LNG Cryogenic Storage Tanks)

LNG cryogenic storage tanks are specialized containers designed to store liquefied natural gas (LNG) at extremely low temperatures. These tanks play a critical role in the energy infrastructure, enabling the safe and efficient storage and transportation of LNG.

Key Technical Specifications

LNG cryogenic storage tanks feature advanced engineering to maintain the ultra-low temperatures required for LNG storage:

Design Temperature: Typically -196°C to accommodate various cryogenic liquids

Working Pressure: Ranges from 0.8 MPa to 1.2 MPa depending on application

Construction Materials: Stainless steel (304L) for inner shell with carbon steel outer shell

Insulation System: Double-walled vacuum insulation with materials

Capacity Range: From 20m³ to 200m³ storage tanks

Industry Applications

LNG cryogenic storage tanks serve diverse applications across multiple industries:

Energy Sector:

LNG receiving terminals and regasification facilities

Peak regulation storage for gas supply networks

Floating storage and regasification units

Transportation:

LNG-powered ships and marine vessels

Heavy-duty trucks and transit buses

Railway applications

Industrial Use:

Remote power generation facilities

Industrial process applications

Electronics manufacturing requiring ultra-cold environments

Safety and Maintenance Considerations

Proper operation of LNG cryogenic storage tanks requires strict adherence to safety protocols:

Pressure Relief Systems: Essential to prevent over pressure conditions

Leak Detection: Advanced sensors to monitor for potential leaks

Regular Inspections: Required to assess insulation integrity and structural condition

Emergency Procedures: Well-defined protocols for handling boil-off gas

Market Trends and Innovations

The global LNG storage tank market is projected to reach over $22 billion by 2028, growing at a CAGR of 7.9%. Key innovations include:

Membrane Tank Technology: Reducing construction costs while maintaining safety

Material Advancements: New molybdenum microalloyed steels for improved low-temperature performance

Smart Monitoring: IoT-enabled systems for real-time tank condition monitoring

For more technical details about specific tank models or applications, please consult Nangong Zhuoyue Gas Equipment Co., LTD.