When hospitals use liquid oxygen storage tanks to supply oxygen, ensuring the stable pressure of the oxygen equipment is crucial. Usually, precise pressure control of the system is achieved through pressure regulating devices. The core principle is to utilize the pressure boosting and regulating system of the liquid oxygen storage tank, combined with multi-stage pressure reduction design, to achieve stable pressure from the source to the terminal.

I. The pressurization and pressure regulation mechanism of the liquid oxygen storage tank

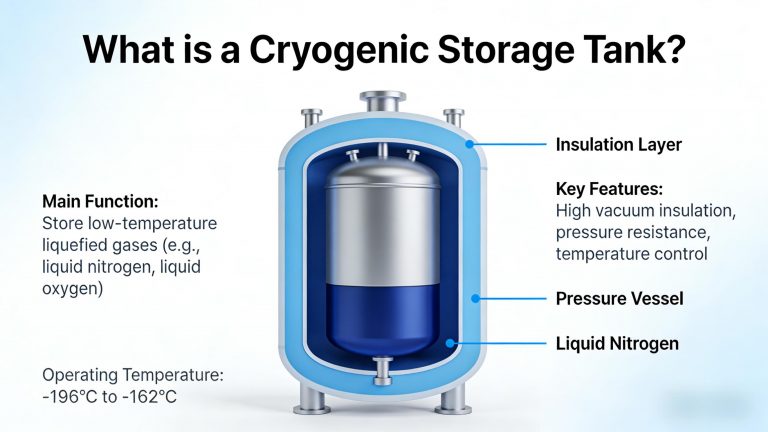

The internal pressure of the liquid oxygen storage tank is affected by natural evaporation (self-evaporation) and oxygen consumption fluctuations, and it is necessary to actively adjust to maintain stable oxygen supply:

Pressurization process: When the pressure inside the tank drops, the system opens the pressurization valve to draw liquid oxygen from the bottom of the tank. The gas is heated and vaporized by the small gasifier and then returned to the gas phase space of the tank from the top, thereby increasing the internal pressure. This process can set a target pressure to achieve automatic start-stop control.

Pressure regulation control: Through the coordinated operation of the pressure increase regulating valve and the pressure reduction regulating valve, the tank pressure is stabilized within the set range. If the pressure is too high, the safety valve will activate to release pressure; if it is too low, the pressurization system will be activated to replenish the pressure.

II. Multi-stage depressurization ensures stable terminal pressure

To meet the oxygen pressure requirements of different departments, the system adopts a multi-stage pressure reduction design:

Primary depressurization: After liquid oxygen is output from the storage tank, it is vaporized through an evaporator and converted into gaseous oxygen. Then, it passes through a primary depressurization device to reduce the pressure to below 0.75 MPa.

Secondary and terminal depressurization: After the gas enters the distribution network, it is further regulated to 0.4 – 0.6 MPa through secondary depressurization boxes in floors or wards, with an error of no more than ±0.02 MPa to ensure constant pressure at each terminal.

III. Safety and Emergency Assurance Measures

Over pressure protection: Two safety valves and rupture discs are set. When the pressure exceeds the safety limit (such as 1.25 times the working pressure), the gas is automatically released to prevent the storage tank from over pressurizing.

Backup system: Most hospitals adopt the “liquid oxygen main supply + manifold backup” mode. When the main system fails, it can automatically switch to the high-pressure oxygen cylinder group within 30 seconds to ensure continuous oxygen supply.

Excellence Gas Equipment specializes in manufacturing medical supply cryogenic storage tanks and also offers gas solutions. If you have any requirements for customizing cryogenic gases, please contact us through our website.