I. What to Do If the Power Goes Out

1.Keeping the Vacuum

If the power goes out, the vacuum valve should shut automatically to keep the tank sealed.

What to do: Shut the vacuum valve yourself, fast, to keep air out.

When the power’s back, check the pipes are less pressurized than inside the tank before opening the valve.

Keep records: Note when the power went out and came back on in the vacuum log.

2.Things to Watch For

Don’t let oil get sucked back from the vacuum pump: Cut off the tank from the pump if the power goes out.

Check the vacuum: After getting the vacuum back, make sure the jacket pressure is steady.

II. How to Seal Things Up Right

1.Keeping the Vacuum Tight

Shut the vacuum valve before sealing, so the tank’s not linked to the vacuum system.

Note the vacuum level after sealing to be sure it’s good.

2.Checking the Seal

Measure directly with a vacuum gauge, when it’s 0°C to 40°C around.

Take three measures on the same tank, then get the average.

III. How to Test the Vacuum Hold

1.When to Test

Measure the vacuum at least four times a day for the first two days after sealing.

Keep records: Note the time and weather with each measure.

2.What Shows a Good Vacuum

Stable vacuum: Watch the pressure, and don’t let it change too much.

How much it leaks: Find this by looking at jacket pressure changes; it must be within the usual amounts.

IV. Keeping Records and Staying Compliant

1.Needed Records

Someone needs to fill out vacuum check records to keep track of everything.

Quality inspectors need to sign off on these, and they get saved to show the gear is okay.

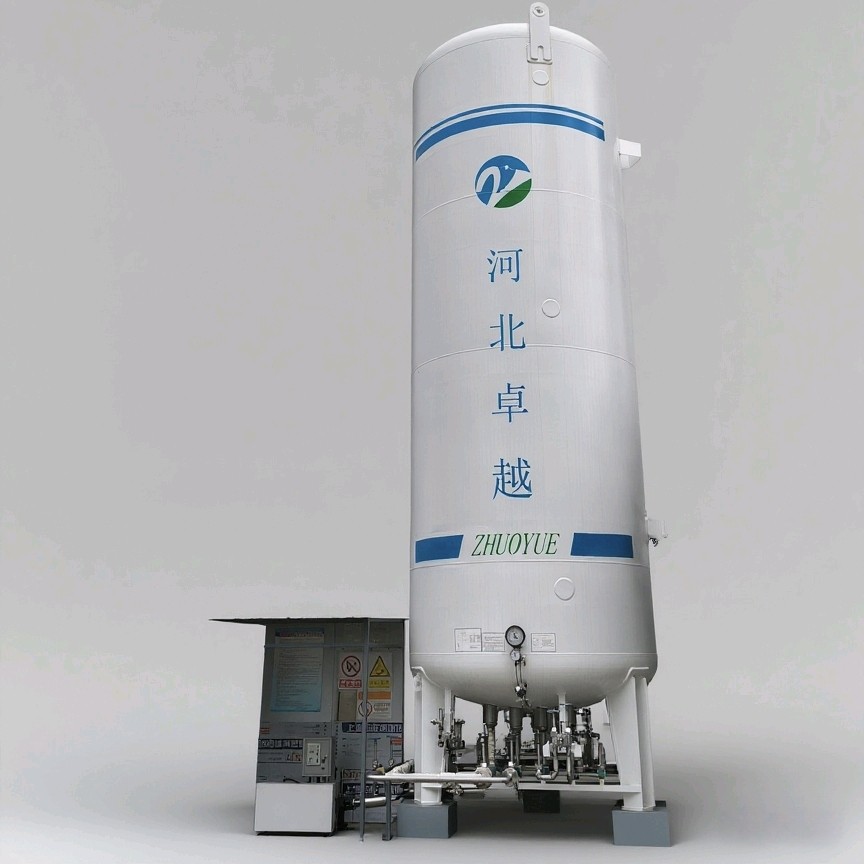

The above is the detailed introduction of the vacuuming process for low-temperature storage tanks. Our outstanding gas equipment specializes in designing and manufacturing various types of low-temperature storage tanks. If you have any requirements for low-temperature storage tank solutions, please contact us through our website.