Product Overview

High Pressure Liquid CO2 Tanks | Industrial Cryogenic Storage

Introduction to High-Pressure Liquid CO2 Tanks

High-pressure liquid CO2 tanks are specialized containers designed for the safe and efficient storage of carbon dioxide (CO2) in its liquid form under extreme pressure conditions. These tanks play a pivotal role in industrial cryogenic storage applications, where maintaining low temperatures and high pressures is essential for preserving the integrity of sensitive materials. Unlike standard storage solutions, they are engineered to withstand the unique challenges posed by cryogenic environments, ensuring long-term stability and minimal risk of leakage or contamination.

Key Features and Design Considerations

1. Robust Construction and Material Selection

Shell Characteristics: The tanks feature shells made from high-strength materials such as steel or fiberglass-reinforced polyester, which provide exceptional durability and resistance to corrosion. The shell color and condition are optimized for industrial aesthetics and longevity, with options ranging from standard shades to custom finishes.

Roof Design: A variety of roof types are available, including cone, dome, and flat roofs, each designed to meet specific storage needs. The roof slope and radius are carefully calculated to ensure proper drainage and structural integrity, while the roof condition is maintained to prevent degradation over time.

2. Pressure and Temperature Control

Breather Vent Settings: These tanks are equipped with adjustable breather vents that allow precise control over the internal pressure. The vacuum and pressure settings can be customized to maintain optimal storage conditions, preventing the build-up of excessive pressure or vacuum that could compromise the tank’s integrity.

Cryogenic Insulation: To maintain the low temperatures required for liquid CO2 storage, the tanks are insulated with advanced cryogenic materials. This insulation minimizes heat transfer, ensuring that the CO2 remains in its liquid state and reducing the risk of phase changes that could lead to pressure fluctuations.

3. Safety and Leak Detection

Leak Detection Systems: Given the odorless and colorless nature of CO2, these tanks are fitted with electronic leak detectors or soapy water tests for connections. In the event of a suspected leak, immediate evacuation of the area is recommended, followed by shutting off the tank and contacting a qualified technician for repairs.

Ventilation and Clearance: Proper ventilation is crucial for preventing the accumulation of CO2 in confined spaces. The tanks should be stored in well-ventilated areas, preferably upright and secured to prevent tipping. A minimum clearance of 3 feet from ignition sources, flammable materials, and heat sources is required to reduce fire risks.

Applications in Industrial Cryogenic Storage

1. Agricultural CO2 Enrichment

High-pressure liquid CO2 tanks are widely used in agriculture to enhance plant growth through CO2 enrichment. The tanks provide a consistent and controlled supply of CO2, which is essential for photosynthesis and can significantly improve crop yields. Their portability and ease of use make them ideal for mobile welding units and remote construction sites.

2. Disaster Relief and Remote Operations

In disaster relief scenarios, these tanks are invaluable for providing a reliable source of CO2 for emergency operations. They can be quickly transported to affected areas and used for various purposes, including fire suppression and medical applications. Their robust design ensures they can withstand the rigors of transportation and deployment in challenging environments.

3. Industrial Processes and Manufacturing

In manufacturing, high-pressure liquid CO2 tanks are used in processes such as welding, cutting, and cleaning. The tanks ensure a steady supply of CO2, which is critical for maintaining the efficiency and quality of these processes. Additionally, they are employed in the production of beverages, where CO2 is used to carbonate drinks, and in the pharmaceutical industry for the storage of temperature-sensitive compounds.

Maintenance and Compliance

1. Regular Inspections and Testing

To ensure the continued safe operation of high-pressure liquid CO2 tanks, regular inspections and hydrostatic tests are essential. These tests typically occur every 5–10 years and involve checking the tank’s structural integrity, pressure levels, and leak detection systems. A detailed log of all inspections, repairs, and maintenance activities should be maintained to support regulatory compliance.

2. Regulatory Compliance

Compliance with local and international regulations is crucial for the operation of these tanks. This includes adhering to standards set by organizations such as OSHA, NFPA, and CGA. Regular training for personnel involved in the handling and maintenance of the tanks is also recommended to ensure they are aware of the latest safety protocols and regulatory requirements.

Conclusion

High-pressure liquid CO2 tanks are a cornerstone of industrial cryogenic storage, offering a safe, efficient, and reliable solution for the storage of liquid CO2 under extreme conditions. Their robust construction, precise pressure and temperature control, and advanced safety features make them indispensable in a wide range of applications, from agriculture to disaster relief. By adhering to proper maintenance and compliance protocols, businesses can ensure the long-term performance and safety of these critical assets.

Specifications

| Model | Volume (M3) | Working pressure (bar) | Dimension (mm) | Weight (KG) | Type | Standard |

|---|---|---|---|---|---|---|

| CFL-5/2.16 | 5 | 21.6 | Φ2000*5130 | 4450 | Vertical | GB ASME |

| CFL-10/2.16 | 10 | 21.6 | Φ2100*7170 | 6986 | ||

| CFL-15/2.16 | 15 | 21.6 | Φ2500*6912 | 8810 | ||

| CFL-20/2.16 | 20 | 21.6 | Φ2500*8756 | 11328 | ||

| CFL-25/2.16 | 25 | 21.6 | Φ2900*7728 | 17961 | ||

| CFL-30/2.16 | 30 | 21.6 | Φ2900*8875 | 14660 | ||

| CFL-50/2.16 | 50 | 21.6 | Φ3200*11320 | 26097 | ||

| CFL-60/2.16 | 60 | 21.6 | Φ3200*13180 | 30220 | ||

| CFL-100/2.16 | 100 | 21.6 | Φ3500*16870 | 49627 |

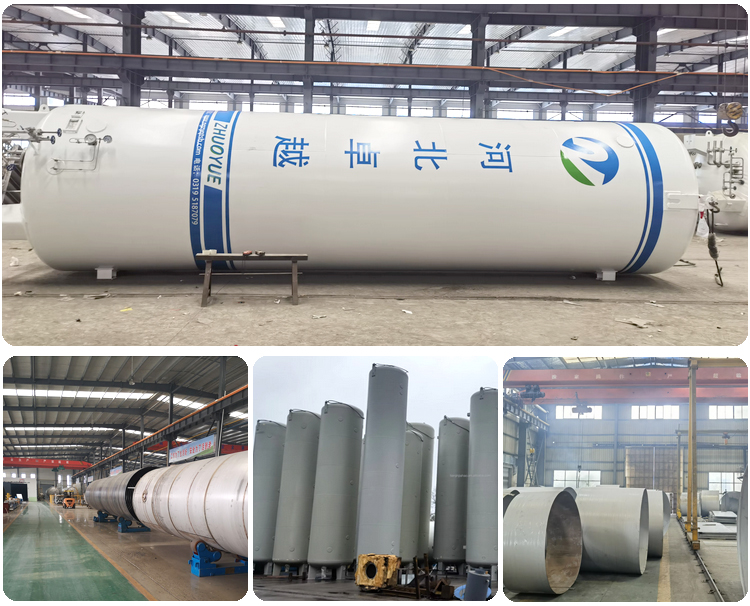

Company Profile

we measure our success by the success of our customers .

Production Workshop

Shipping & Packaging

Certifications