The inspection of the process flow is a crucial step in the manufacturing process of petrochemical storage tanks, directly influencing the quality and safety of the products. As the person responsible for process quality control, this monthly activity is led by the department in charge of process quality control. It involves multiple departments such as the Quality Inspection Department, the Process Department, the Enterprise Management Department, and the Production Department, and focuses on key processes such as storage, cutting, forming, welding, assembly, hydrostatic testing, and non-destructive testing. The core purpose of this inspection is to ensure the consistency of production standards and to specifically verify the effectiveness of the rectification of problems identified in the previous stage.

Core content inspection

Personnel qualification management: Special equipment operators must hold valid operation certificates to be able to perform their duties, and their operation scope must be strictly limited to the items they have passed the assessment for.Unauthorized or over-range operations must be strictly prevented.

Knowledge of process documents: Inspectors and operators must be proficient in the drawings, process requirements, and testing methods to ensure that each process adheres to the standard procedures and avoids quality fluctuations due to misunderstandings.

Equipment and measuring tool maintenance: The technical condition of equipment must be maintained in good condition. Measuring tools, inspection tools and instruments need to be regularly calibrated to ensure uniform measurement values and measurement accuracy, and to prevent production defects caused by equipment errors.

Component management: The storage, preservation and identification of components must comply with the process specifications. Substituted materials must go through formal procedures to ensure traceability and compliance.

Process document control: The documents should clearly define the quality control points and the qualification standards. Any changes must be carried out in accordance with the procedures to avoid arbitrary modifications that could disrupt the stability of the process.

Production environment guarantee: The production environment conditions must meet the manufacturing requirements, including safety and civilized production standards, in order to reduce the potential risk of accidents.

Inspection records and identification: The inspection process should be recorded promptly and status labels should be applied to ensure traceability of issues. At the same time, the closed-loop management of problems identified in the previous inspection should be strengthened.

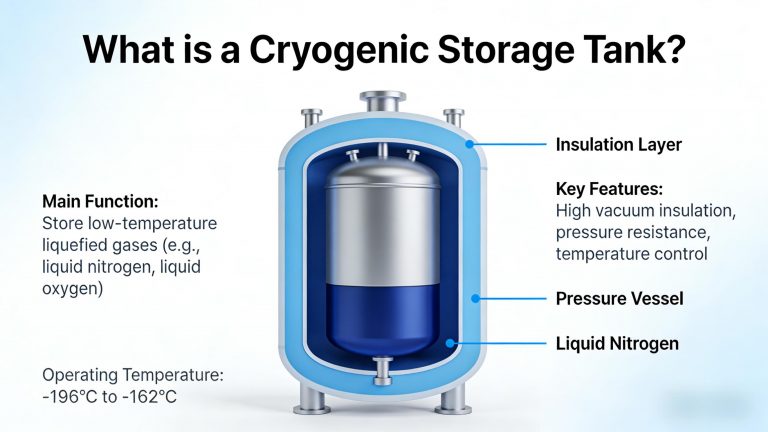

The above is the specific content of the inspection on the process discipline of the liquefied gas storage tanks. Our company, “Excellence Gas Equipment”, specializes in the production of cryogenic liquid storage tanks. If you have any requirements for gas solution customization, please contact us through the website. We will reply to you as soon as possible.