“General Characteristics of Liquefied Natural Gas” (GB/T19204-2003): LNG (liquefied natural gas) is a hydrocarbon mixture with methane as the main component, which contains a small amount of ethane, propane, nitrogen and other components usually present in natural gas. point.

LNG character

- Components: The main component is CH4, and there are a small amount of ethane C2H6, propane C3H8, nitrogen N2, and other components.

- Density: The density of LNG depends on its components, usually between 430kg/m3-470 kg/m3, when LNG is transformed into a gas, its density is 1.5kg/m3, heavier than air, when the temperature rises to – At 107°C, the gas density is similar to the air density.

- Boiling point: The boiling point depends on its components, usually between -166°C and -157°C at atmospheric pressure

- Explosion range: the upper limit is 14%, and the lower limit is 5%.

- Colorless, odorless, non-toxic and non-corrosive

- The volume is about 1/625 of the volume of the same amount of gaseous natural gas.

LNG storage tank classification and structure

Liquefied natural gas storage tanks are professional products for storing liquefied petroleum gas, special equipment, and second-class pressure vessels.

LNG storage tank Classification

Classified by capacity:

- Small size (5~50 m3): It is often used in civilian LNG vehicle filling points and civil gas liquefaction stations.

- Medium-sized (50~100 m3): mostly used in industrial gas liquefaction stations.

- Large (100~1000m3): suitable for small LNG production units

- Super-large (10000~40000m3): used for base-load and peak-shaving liquefaction plants.

- Extra large (40000~200000m3): used for LNG receiving station.

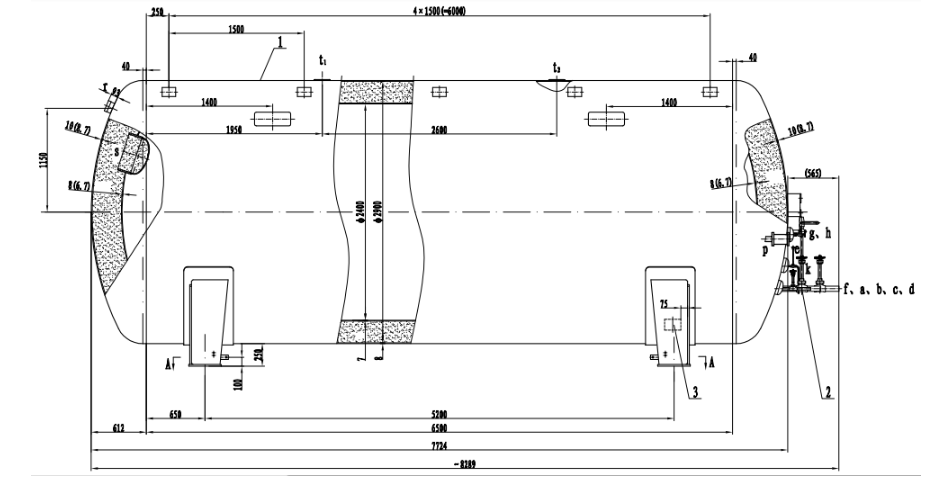

LNG storage tank structure and construction

Structure of LNG storage tank

The cryogenic storage tank has a double-layer structure. The inner tank stores low-temperature liquid and withstands the pressure and low temperature of the medium. The material of the inner tank is made of low-temperature resistant alloy steel (0Cr18Ni9); the outer shell is the protective layer of the inner tank, and a certain Spacing, forming a thermal insulation space, bearing the gravity load of the inner tank and the medium and the vacuum negative pressure of the thermal insulation layer. The shell is not exposed to low temperature and is made of container steel. Most of the heat insulation layer is filled with pearlite and vacuumed. The evaporation rate of cryogenic storage tanks is generally less than 0.2%.

Mainly include: outer tank, inner tank, inner tank support, heat insulation layer, upper and lower liquid inlet and upper and lower liquid level pipes, gas phase pipe, overflow pipe, liquid outlet pipe, and safety accessories and instruments.

The role of each part:

- Outer tank: protect the inner tank and the cold insulation material between the inner and outer tanks, and form a vacuum between the inner and outer tanks to improve the cold insulation performance of the cold insulation material. The outer tank can completely block the leaked liquid and vapor to ensure safe storage

- Inner tank: It mainly stores LNG, but due to the ultra-low temperature characteristics of LNG, the requirements for tank materials and production are extremely strict.

- Upper and lower liquid inlet pipes: It should be noted that the length of the upper liquid inlet pipe is similar to that of the inner tank. The liquid inlet pipe in the storage tank uses a mixing nozzle and a porous pipe to fully mix the newly filled LNG with the original LNG.

- Safety valve: When the pressure in the storage tank exceeds the setting pressure of the safety valve (also called the working pressure), the safety valve will automatically open to release excess gas and stabilize the pressure. The setting pressure of the safety valve is generally 1.04-1.1 times the working pressure of the pressure vessel, and the reseating pressure is 0.8 times the working pressure of the pressure vessel.

- Bursting disc of the outer tank: it is to prevent leakage at the root of the connection between the inner tank and the pipeline. The pressure increase between the interlayers will cause the explosion of the outer tank. The bursting disc is installed to release the pressure in time to protect the storage tank

- Differential pressure level gauge: a differential pressure level gauge generally used in LNG storage tanks

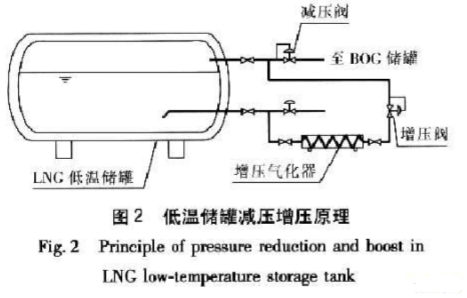

Principle of pressure reduction and boost in LNG low-temperature storage tank

The liquid outlet of the cryogenic storage tank is driven by the self-pressure of the storage tank. After the liquid is sent out, the liquid level drops and the gas phase space increases, causing the pressure in the tank to drop. Therefore, it is necessary to continuously add gas to the tank to maintain the pressure in the tank to meet the process requirements. As shown in the figure, there is a booster vaporizer and a booster valve under the storage tank. The booster vaporizer is an air-temperature vaporizer, and its installation height is lower than the minimum liquid level of the storage tank. The action of the pressure increasing valve is opposite to that of the pressure reducing valve. It opens when the outlet pressure of the valve is lower than the set value, and closes when the pressure rises above the set value.

The pressurization process is as follows: When the pressure in the tank is lower than the set value of the booster valve, the booster valve opens, the liquid in the tank slowly flows into the booster vaporizer by the liquid level difference, and the gas generated by the gasification of the liquid flows through the booster valve. The valve and gas line are added to the storage tank. The continuous replenishment of gas makes the pressure in the tank rise, and when the pressure rises above the set value of the booster valve, the booster valve is closed. At this time, the pressure in the supercharger will prevent the liquid from continuing to flow in, and the supercharging process is over.

Decompression: (overpressure protection)

During the storage process of LNG, the pressure of the storage tank will gradually increase due to the slow evaporation due to the environmental heat leakage of the storage tank, which will eventually endanger the safety of the storage tank.

Therefore, the method of releasing the gas in the tank must be used to control the upper limit of the pressure. The method is to install a pressure regulator on the gas phase pipeline of the storage tank. The internal gas is released, and when the pressure drops back below the set value, the automatic pressure regulator will automatically close. It should be pointed out that the pressure regulator mentioned here is not our commonly used gas pressure regulator. Generally, the regulator depends on the pressure at the outlet to control the action of the valve, but this kind of regulator depends on the pressure at the inlet to control the action of the valve, like our commonly used relief valve, and it must withstand low temperature. The released gas is generally not put into the atmosphere, and the subsequent process will recycle it. This part of the gas is referred to as BOG.

Advantage of Zhuoyue LNG cryogenic storage tank

The inner container of the LNG storage tank of Zhuoyue Company uses S30408 stainless steel plate, which is a 2-meter-wide stainless steel plate custom-rolled by TISCO (Which is the best stainless steel factory in China ); Q345R steel plate is used for the shell.

Our tanks have 5 fewer welds than others. And all welds have to do all radiography and penetrant testing, so our storage tanks are safe and beautiful compared to other suppliers.

Zhuoyue liquefied natural gas storage tanks are manufactured through flaw detection, hydraulic pressure test, external rust removal and painting, and the pressure vessel inspection certificate is issued by the Technical Supervision Bureau on-site inspection. Liquefied gas storage tanks have strict quality appraisal on the material of pressure components, appearance size, weld quality, operation quality, installation quality, internal devices and safety accessories, and routine physical and chemical inspections of tank materials. Such as: mechanical properties and chemical composition.

The welded joints, welds, tank heads, and the geometric positions of the pressure components have passed strict X-ray non-destructive testing and magnetic particle testing.

Inspection and testing of the sealing and pressure resistance of the product, and all technical indicators that can affect the safe operation of the product.

More details or inquiry ,click the follow button to get offer