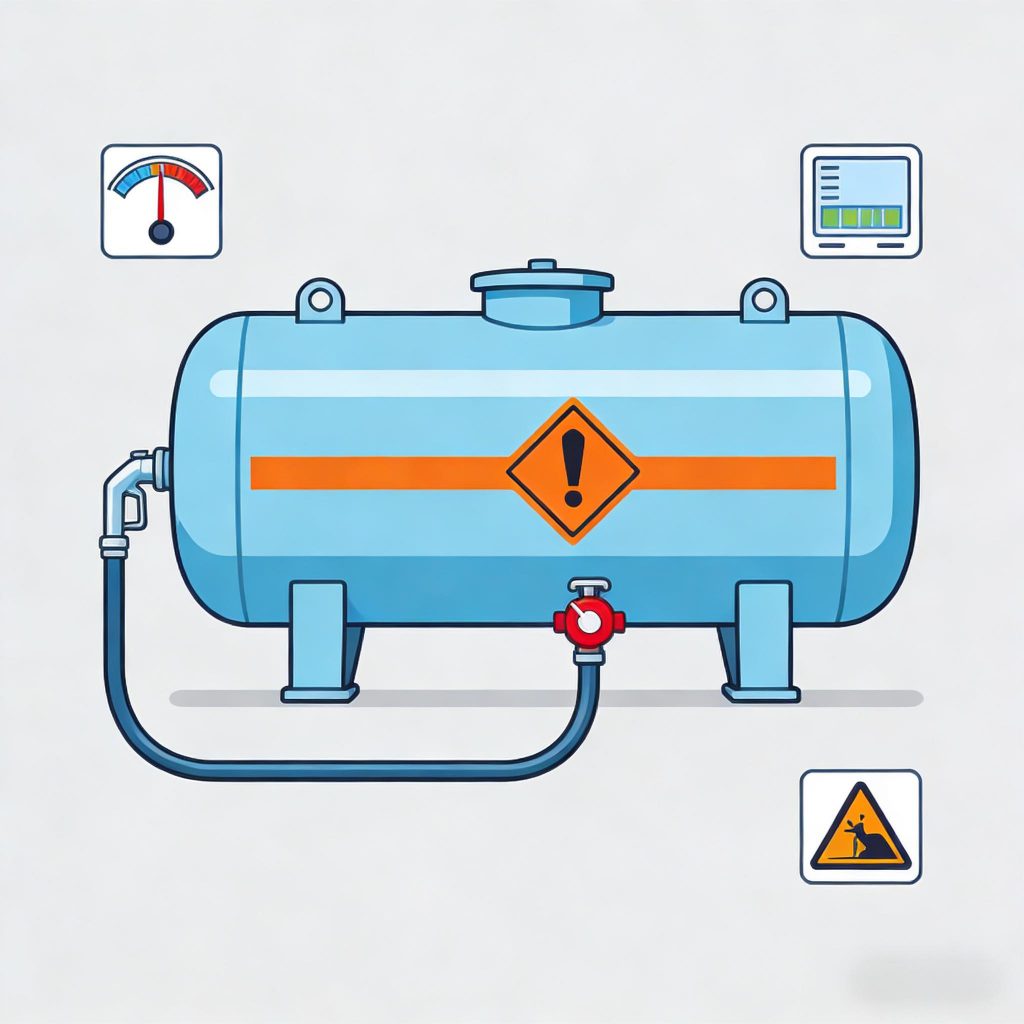

Filling cryogenic storage tanks requires careful preparation and strict safety protocols. Here’s a streamlined version of the key requirements:

Before Filling

1.Pre-Filling Checks

Verify liquid level indicators and pressure gauges

Confirm all valves are in correct positions

Ensure all piping is clear and leak-free

Activate pressure monitoring systems

2.Purge Requirements (for high-purity gases)

Purge with dry nitrogen for 8+ hours

Use product gas for final purging

Light gases (nitrogen): fill from top, vent from bottom

Heavy gases (oxygen/argon): fill from bottom, vent from top

Repeat until gas purity meets standards

Purge all connecting pipelines

Maintain slight positive pressure after purging

During Filling

1.Standard Filling

Keep tank at atmospheric pressure

Open vent valve during filling

Close vent only after completion

2.Special Cases

For rare/valuable liquids: pre-cool with liquid nitrogen first

May use pressurized filling after proper purging

Key Safety Practices

Never mix oxygen systems with combustible gases

Test for leaks before initial use

Train staff on emergency procedures

Maintain proper ventilation

Keep fire extinguishers accessible

Have spill control measures ready

Maintenance Tips

Regularly inspect seals and gaskets

Follow preventive maintenance schedule

Conduct periodic pressure vessel testing

In conclusion, safe and efficient filling of cryogenic storage tanks depends on strict adherence to systematic pre-filling preparations, precise filling operations, strict safety protocols, and consistent maintenance procedures. Fully implementing these principles can effectively reduce operational risks, extend the service life of equipment, and ensure the stable and reliable performance of the low-temperature storage system.