Product Overview

Our liquid carbon dioxide (LCO₂) storage tanks are designed to meet the strict requirements of modern applications. These containers are designed to be safe, efficient and durable, making them an ideal choice for industries ranging from food processing to environmental management. Our storage tanks, backed by precise manufacturing and advanced engineering technology, ensure excellent performance in storing and transporting liquid carbon dioxide under controlled conditions.

Key features

Robust structure: Made of high-grade stainless steel, the storage tank is corrosion-resistant and can withstand extreme pressure, ensuring long-term reliability in harsh environments.

Pressure management: Equipped with a complex pressure control system, it maintains a set pressure above the carbon dioxide solidification threshold to prevent clogging and ensure smooth operation.

Temperature regulation: Integrated insulation and cooling components keep the liquid CO₂ at a stable temperature, effectively reducing evaporation and maintaining the integrity of the product during storage and transportation.

Safety compliance: The design complies with international safety standards, including the United Nations’ regulations on non-flammable gases, and features functions such as emergency safety valves and robust sealing barriers.

Customizable configuration: Various sizes and capacities are available, and heating, insulation, and additional accessories tailored to specific customer needs can be selected.

Applications

Our liquid carbon dioxide tanks serve diverse industries with efficiency and reliability:

Food and Beverage: Used in carbonating drinks, freezing applications, and food preservation, ensuring consistent quality and freshness.

Industrial Processes: Critical for metal working, oil recovery, and foundry operations, where CO₂ acts as a solvent or processing aid.

Environmental Solutions: Supports carbon capture and utilization (CCU) initiatives, aiding in reducing emissions by repurposing CO₂ for chemical synthesis or enhanced oil recovery.

Healthcare and Laboratory: Essential for medical applications, such as anesthesia and in vitro cell culture environments, where precise CO₂ levels are vital.

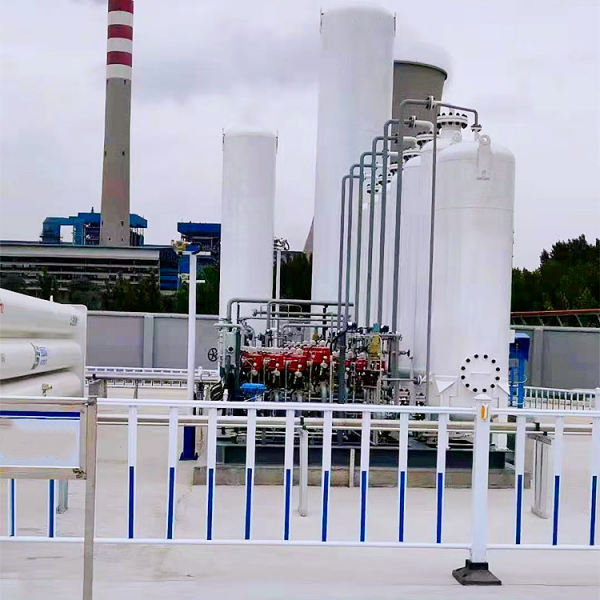

Energy Sector: Facilitates the storage and transport of CO₂ in renewable energy projects, including power plant integration and post-combustion capture systems.

Specifications

| Model | Volume (M3) | Working pressure (bar) | Dimension (mm) | Weight (KG) | Type | Standard |

|---|---|---|---|---|---|---|

| CFL-5/2.16 | 5 | 21.6 | Φ2000*5130 | 4450 | Vertical | GB ASME |

| CFL-10/2.16 | 10 | 21.6 | Φ2100*7170 | 6986 | ||

| CFL-15/2.16 | 15 | 21.6 | Φ2500*6912 | 8810 | ||

| CFL-20/2.16 | 20 | 21.6 | Φ2500*8756 | 11328 | ||

| CFL-25/2.16 | 25 | 21.6 | Φ2900*7728 | 17961 | ||

| CFL-30/2.16 | 30 | 21.6 | Φ2900*8875 | 14660 | ||

| CFL-50/2.16 | 50 | 21.6 | Φ3200*11320 | 26097 | ||

| CFL-60/2.16 | 60 | 21.6 | Φ3200*13180 | 30220 | ||

| CFL-100/2.16 | 100 | 21.6 | Φ3500*16870 | 49627 |

Company Profile

we measure our success by the success of our customers .

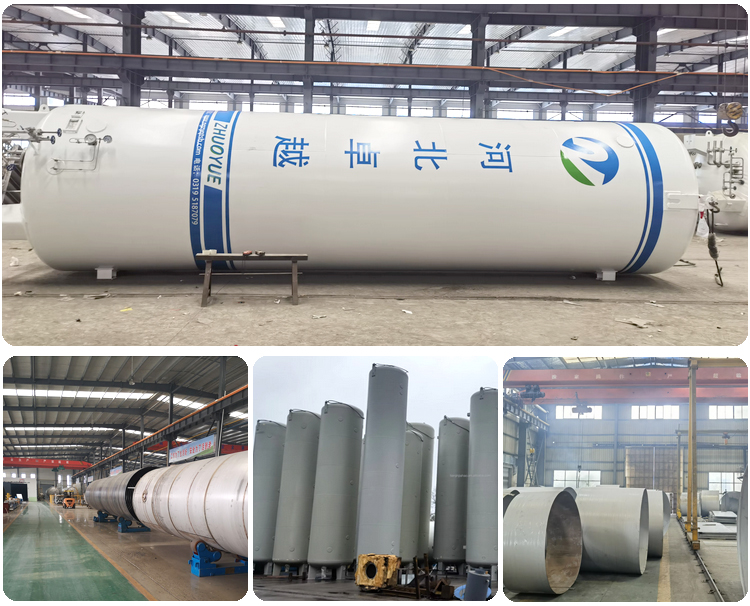

Production Workshop

Shipping & Packaging

Certifications