Product Overview

●Technical Specifications:

Capacity Range: 10-100 cubic meters

Design Configuration: Horizontal orientation

Pressure Rating: Low-pressure design (0.2-3.0 MPa)

Certification: ASME certified with U-stamp compliance

Temperature Range: -40°C to +50°C operational capability

Our advanced cryogenic liquid carbon dioxide storage tanks represent the cutting-edge level of industrial gas storage technology. They are specifically designed for enterprises that require reliable, efficient, and safe carbon dioxide storage solutions. These horizontal tanks integrate advanced vacuum insulation technology with a sturdy structure in accordance with ASME standards, demonstrating outstanding performance in various industrial applications.

●Advanced engineering features

Outstanding insulation system

Our horizontal carbon dioxide storage tanks employ a high-vacuum multi-layer insulation technology and utilize high-quality perlite insulation materials. This advanced insulation barrier system effectively reduces heat transfer, lowers the evaporation rate, and ensures a stable storage state.

Sturdy structural standards

Our storage tanks are made of high-quality materials, including 16MnDR stainless steel inner tanks and Q345R carbon steel shells, which can withstand extreme operating conditions. The double-layer wall structure creates an extremely durable storage system that can withstand thermal cycles, seismic loads and transportation stresses while maintaining structural integrity.

Precise pressure management

These storage tanks are specifically designed for low-pressure operations and are equipped with advanced pressure regulation systems, including dual safety relief valves, differential pressure level indicators, and automatic pressure monitoring. This design not only ensures safe operation but also effectively reduces energy consumption and operational costs.

●Industry Applications and Use Cases

Food and Beverage Processing

Ideal for beverage carbonation systems, food freezing applications, and brewery operations requiring consistent CO₂ supply. Our tanks serve major breweries, bottling plants, and food processing facilities with reliable liquid CO₂ storage for production processes.

Industrial Manufacturing

Perfect for welding operations, chemical processing, pharmaceutical manufacturing, and metal fabrication industries. The horizontal configuration facilitates easy installation in facilities with height restrictions while providing large-volume storage capacity.

Dry Ice Production

Optimized for facilities producing dry ice blocks and pellets, our tanks maintain CO₂ in optimal liquid state for efficient dry ice manufacturing processes. The consistent pressure and temperature control ensures maximum production efficiency.

Environmental Applications

Suitable for greenhouse operations, water treatment facilities, and environmental remediation projects requiring controlled CO₂ delivery systems.

Technical Advantages

Specifications

| Model | Volume (M3) | Working pressure (bar) | Dimension (mm) | Weight (KG) | Type | Standard |

|---|---|---|---|---|---|---|

| CFL-5/2.16 | 5 | 21.6 | Φ2000*5130 | 4450 | Vertical | GB ASME |

| CFL-10/2.16 | 10 | 21.6 | Φ2100*7170 | 6986 | ||

| CFL-15/2.16 | 15 | 21.6 | Φ2500*6912 | 8810 | ||

| CFL-20/2.16 | 20 | 21.6 | Φ2500*8756 | 11328 | ||

| CFL-25/2.16 | 25 | 21.6 | Φ2900*7728 | 17961 | ||

| CFL-30/2.16 | 30 | 21.6 | Φ2900*8875 | 14660 | ||

| CFL-50/2.16 | 50 | 21.6 | Φ3200*11320 | 26097 | ||

| CFL-60/2.16 | 60 | 21.6 | Φ3200*13180 | 30220 | ||

| CFL-100/2.16 | 100 | 21.6 | Φ3500*16870 | 49627 |

Company Profile

we measure our success by the success of our customers .

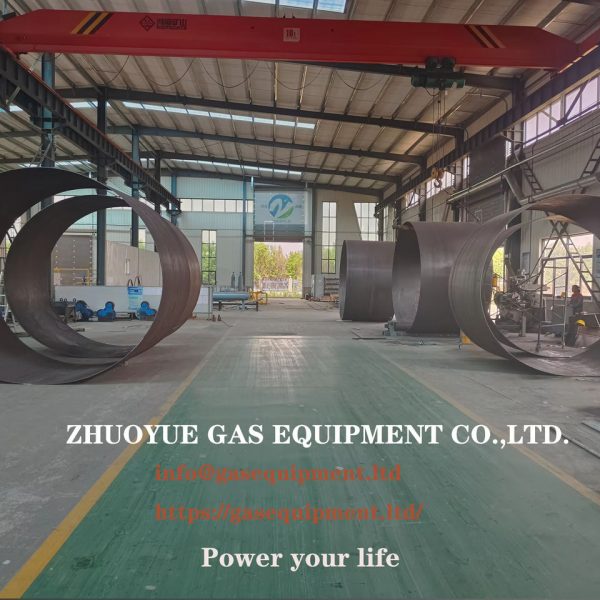

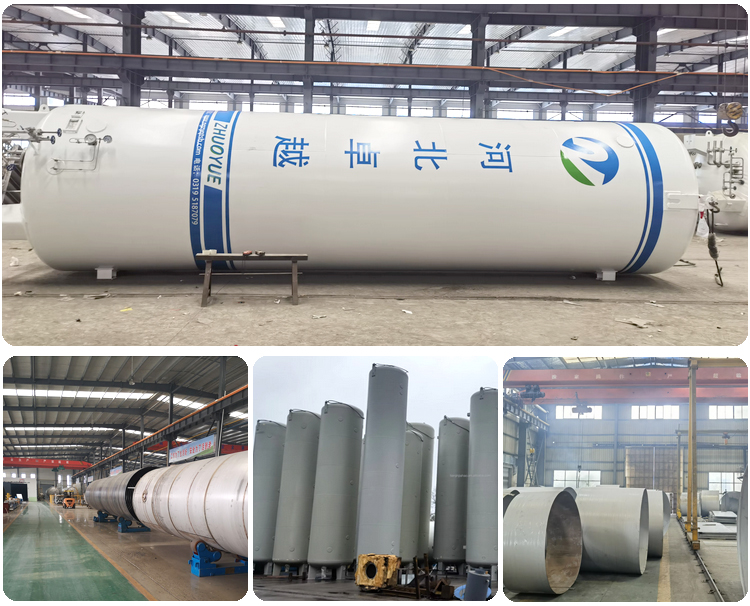

Production Workshop

Shipping & Packaging

Certifications