To extend the service life of cryogenic liquid storage tanks, efforts should be made from multiple aspects such as daily maintenance, standardized operation, and regular inspection. The following are the key measures summarized based on industry practices and norms:

I. Daily Inspection and basic Maintenance

Sealing check : Regularly inspect the neck sealing ring to ensure there is no looseness or air leakage. If any abnormality is found, replace it in time .

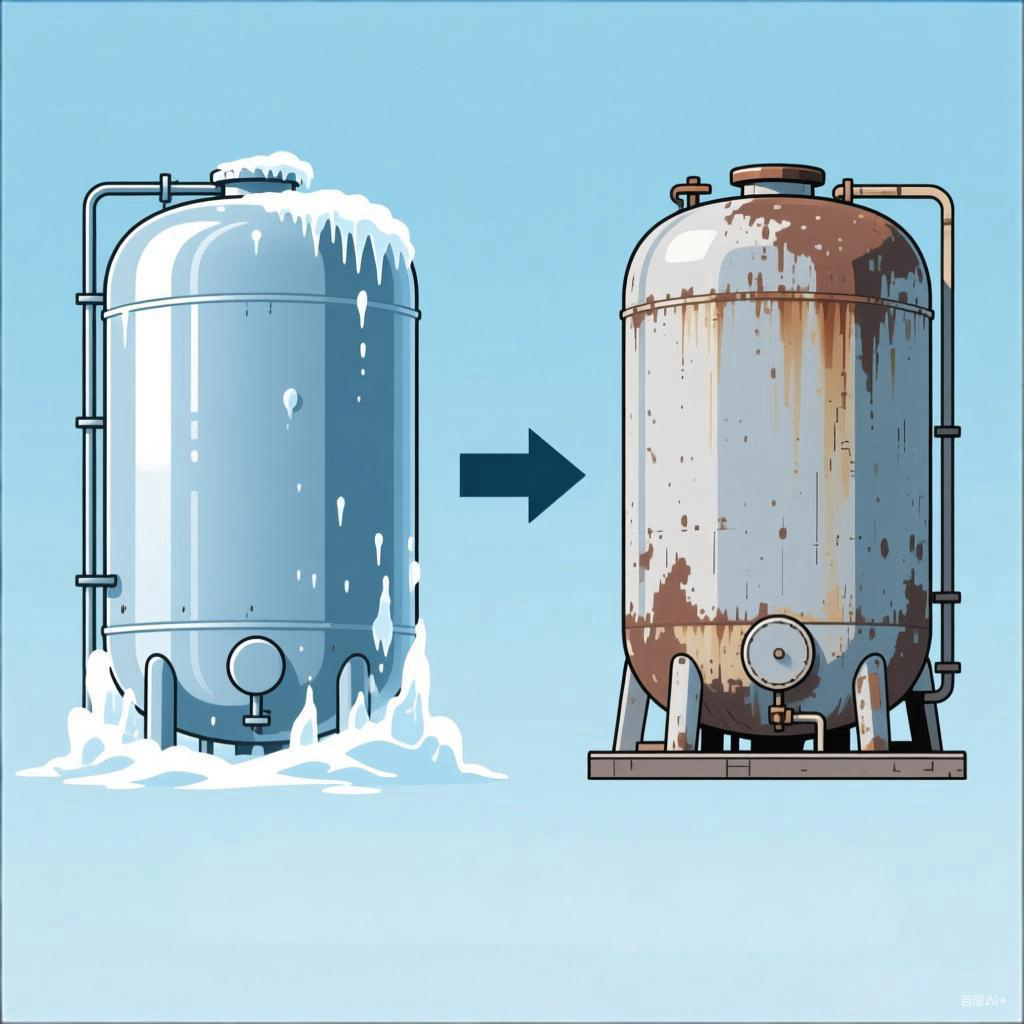

Appearance monitoring : Observe whether the surface of the tank is frosted, deformed or corroded. Local frosting (not in the neck area) may indicate damage to the vacuum layer, which needs to be marked and repaired .

Valve maintenance : Apply low-temperature grease to the moving parts of the safety valve and booster valve every month to ensure smooth opening and closing .

Ii. Deep Cleaning and Material Protection

Inner tank cleaning : After emptying the liquid nitrogen and letting it stand at room temperature every year, wipe the inner wall with a neutral detergent (pH=7-8) and a soft cloth. Avoid using strong acids, strong alkalis or steel wool balls .

Drying treatment : After cleaning, the inner tank should be purged with dry nitrogen to prevent moisture residue from causing ice formation and blockage .

External maintenance : Wipe the surface of the tank with anhydrous ethanol. Passivation treatment can be carried out once a year to enhance corrosion resistance .

Iii. Maintenance of Vacuum Layer and Thermal Insulation Performance

Vacuum degree testing : new tanks should be tested once a year, and tanks that have been in use for more than 5 years should be tested every six months. If the evaporation rate of liquid nitrogen increases by 50% compared to the initial value, the vacuum degree should be detected immediately.

Cold insulation material inspection : Ensure that the interlayer cold insulation material (such as rigid foam ethyl carbamate) is undamaged. Mixing powder and fibrous materials can enhance the insulation effect.

Iv. Standardized Operations and Environmental Control

Installation requirements : The foundation must be level and capable of withstanding pressure. Wooden or iron plates should be laid in the gaps of the steel structure to avoid direct sunlight and slow down aging.

Temperature monitoring : Install intelligent temperature sensors to monitor the temperature fluctuations inside the tank in real time and make timely adjustments in case of abnormalities .

Avoid extreme temperatures : When the tank is on the edge of the temperature limit for a long time (such as close to -10℃ or 70℃), enhanced monitoring is required to prevent the tank from becoming brittle or softening .

V. Regular professional inspection and update

Comprehensive inspection : Conduct a comprehensive “physical examination” of the storage tank every three years, including weld inspection (magnetic particle inspection, vacuum airtightness inspection) and evaluation of insulation materials.

Component replacement : Equipment that has exceeded its designed service life must undergo mandatory annual inspection, and aged components (such as sealing rings and valves) should be replaced in a timely manner .

Through the above measures, the failure rate can be significantly reduced and the service life of the cryogenic liquid storage tank can be prolonged.