Cryogenic tanks are containers specifically designed for storing liquid gases, and they operate at extremely low temperatures. Cryogenic tanks tanks have extensive applications in fields such as energy, aerospace, electronics, manufacturing, and healthcare. In these industries, applications such as liquid nitrogen, liquid oxygen, and liquid argon require precise temperature control.

Core Principles of Cryogenic Storage

Cryogenic liquids are cooled to a gaseous state through compression and expansion processes. Storing them at extremely low temperatures can minimize evaporation, enabling controlled release when needed.The tank must maintain these temperatures while preventing heat from the environment from entering and managing pressure buildup from vaporization.

Key Components

Vacuum Insulation

Modern tanks use vacuum insulation to create a barrier between the inner and outer walls, reducing heat transfer. Some designs include aerogel materials for enhanced insulation.

Pressure Management

Pressure control systems ensure safe operation through:

- Pressure relief valves

- Boil-off gas management

- Active pressurization

Structural Design

Tanks are built with double-walled stainless steel or aluminum, reinforced to handle thermal contraction and prevent leaks.

How Storage Works

- Filling: Cryogenic liquid is pumped into the tank through fill ports designed to minimize heat ingress.

- Insulation: The vacuum insulation system maintains the temperature difference between the liquid and surroundings.

- Vaporization: A small amount of liquid naturally vaporizes, creating pressure in the vapor space.

- Pressure Control: The system regulates pressure by venting or using vapor for pressurization.

- Withdrawal: Liquid is drawn from the tank through bottom withdrawal systems or vaporizers as needed.

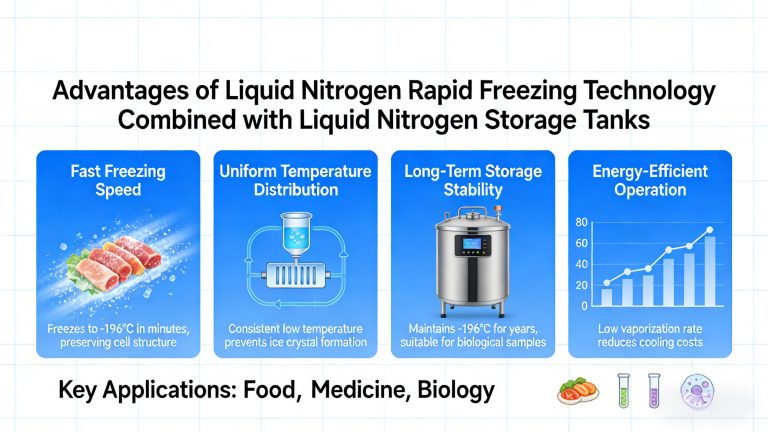

Applications

Cryogenic tanks support diverse industries:

- Energy: Storage for renewable power systems.

- Healthcare: Preserving biological materials.

- Aerospace: Rocket fuel storage.

- Industrial Processes: Applications requiring extreme cold.

Safety Features

Safety is prioritized with:

- Redundant pressure relief systems.

- Thermal monitoring sensors.

- Emergency venting capabilities.

- Robust containment designs.

Conclusion

Cryogenic tanks have extensive applications in the engineering field, enabling various industries to safely and efficiently handle gases in a low-temperature state.As technology advances, these tanks continue to evolve, offering improved performance and reliability across scientific and technological fields.