1.Why Meat Must Be Frozen “Fast”

Ice crystals are meat’s worst enemy. A conventional –30 °C blast freezer needs 6–12 h, giving crystals time to grow into jagged spears that puncture cell walls. The result: 5–10 % drip loss after thawing—and the flavor, color, and water-soluble vitamins disappear with the blood.

Liquid-nitrogen (LN₂) flash-freezing compresses the same process into 10–30 min:

- Cooling rate 7–15 °C per minute blasts through the critical –1 °C to –5 °C zone where most ice forms

- Ice crystals stay <20 µm—one-fifth the size of those in a regular freezer

- Cells remain almost intact; thaw drip is <1 %, and the steak still looks, smells, and bounces like it just left the slaughter line

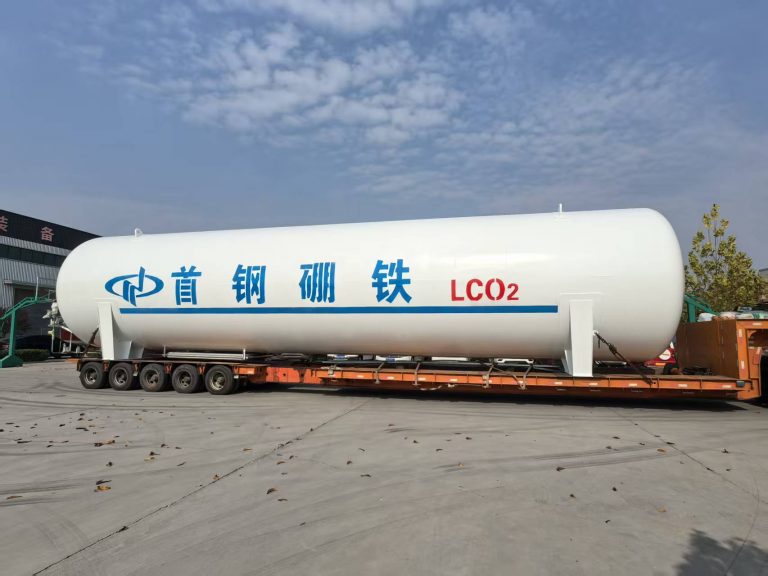

2.LN₂ Tank: A –196 °C “Mobile Cold Room”

An LN₂ storage tank is no thermos flask; it is a cryogenic pressure vessel:

- Double-wall vacuum + perlite: inter-space vacuum ≤3 Pa kills convection and conduction; 0.8–1.2 mm perlite beads cut radiation, holding static evaporation ≤0.3 % per day

- 316 L stainless inner shell: retains 205 J impact toughness at –196 °C, preventing thermal-fatigue cracks

- Modular manifolds: one tank can feed 3–10 tunnels, each handling 50–300 kg/h—perfect for plants processing 1–50 t per day

3.Three Proven Use-Cases for LN₂ Meat Freezing

a) Premium steak / Wagyu

After a 55 °C core sear, a 3-min LN₂ tunnel forms a vitrified micro-coating that locks in juices; the steak still eats “Michelin” after retail thaw.

b) Hot-pot beef rolls

1.2 mm-thick slices freeze in 30 s. Ice is uniform, so rolls stay intact after 8 s in boiling broth—zero blood loss and +15 % upsell price.

c) Ready meals / e-commerce

Seamless hand-off to –18 °C cold chain; survives ±5 °C swings. Shelf life doubles to 12 months and return rates drop 50 %.

4.Cost & Pay-Back: Real 500 kg/h Line Data

- LN₂ consumption: 0.28 kg per kg beef

- Energy: 65 % less electricity vs. spiral freezer; eliminates 60 HP refrigeration package

- ROI: at 70 % capacity utilization, pay-back in 14 months. Premium positioning adds CNY 20/kg margin—effectively doubling gross profit

5.Take-Off: Meat Freezing Enters the “Seconds” Era

From cell-level freshness to lower cold-chain bills, LN₂ tanks are rewriting meat-processing rules. Master three levers—cooling rate, final core temp, and air velocity—and you can replicate glassy flash-freezing in a plant, central kitchen, or even a mobile pop-up unit, turning “zero drip loss” into brand premium.