Core Advantages: Efficient and Safe Liquid Oxygen Storage System

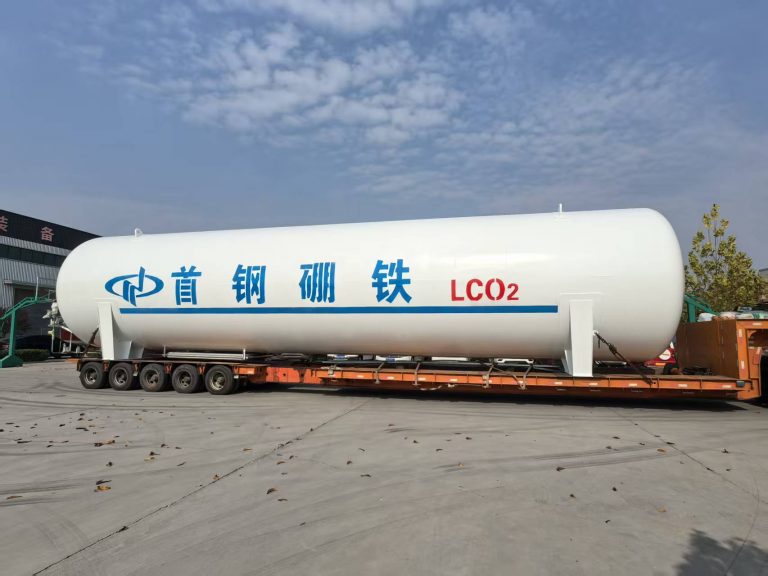

The cryogenic liquid oxygen storage tanks produced by Exquisite Gas Equipment are industrial-grade pressure vessels, specifically designed for the safe storage of liquid oxygen. As fixed pressure vessels, we offer both vertical and horizontal structural options, with specifications ranging from 5 cubic meters to 200 cubic meters, to meet the diverse needs of enterprises of different scales.

It has wide applications in various fields.

Our liquid oxygen storage tank system plays a significant role in several key areas:

Steel manufacturing: Supporting efficient production processes in steel mills

Medical health: Providing reliable medical oxygen sources for hospitals

Food processing: Ensuring hygiene standards in the food and beverage industry

Welding technology: Meeting the high-purity gas requirements of the welding industry

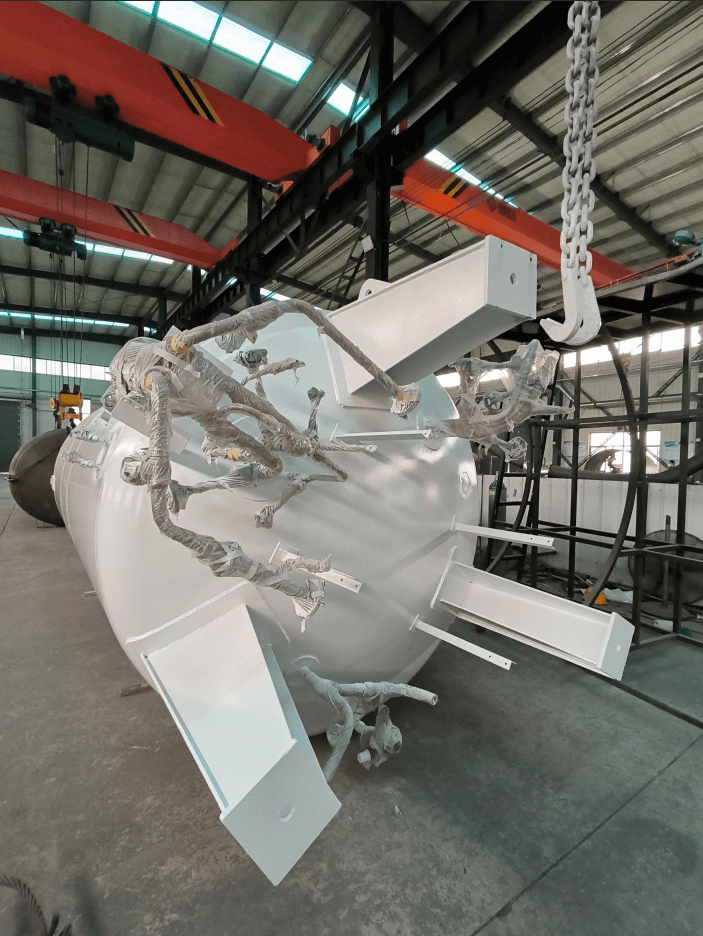

Innovative design: Double-layer structure for safety

High-quality material combination

he tank is designed with a double-layer structure:

Inner liner and piping: Austenitic stainless steel material, ensuring corrosion resistance and long-term stability

Shell: Q245R or Q345R carbon steel plate, providing robust protection

Advanced insulation technology

The insulation layer is filled with pearlescent sand and then vacuum treatment is carried out. The vacuum degree exceeds the requirements of industry standards. This design effectively reduces heat transfer, maintains the low temperature of liquid oxygen, and significantly reduces evaporation loss.

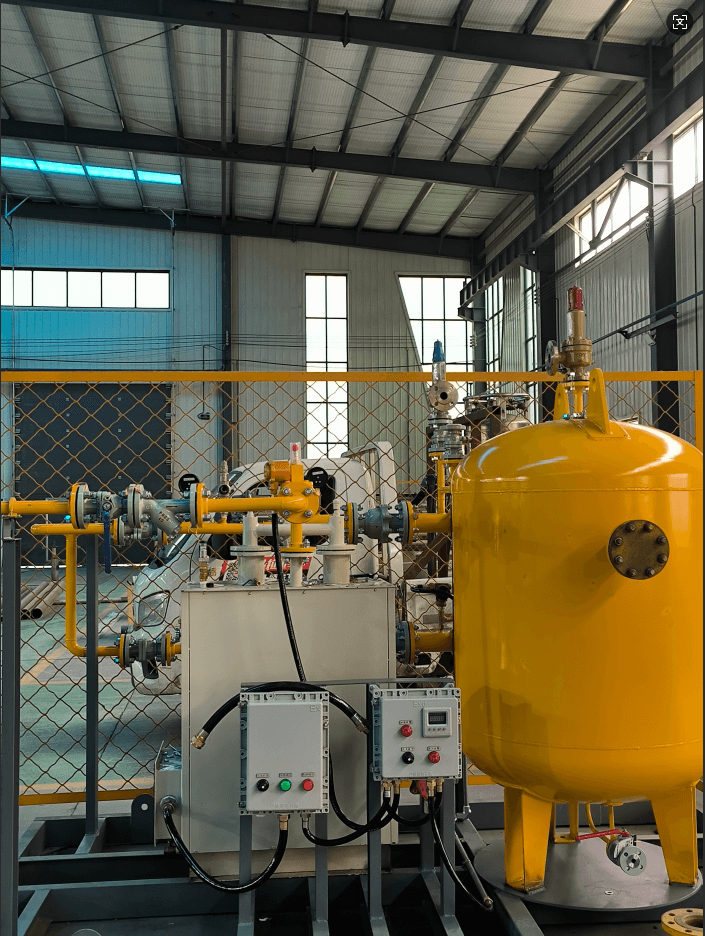

Pressure regulation flexibility

The inner liner of the storage tank offers two working pressure options of 0.8 MPa and 1.6 MPa. Within the pressure range permitted by the equipment, users can flexibly adjust the working pressure according to their actual needs to achieve the best operational efficiency.

Usage Instructions: The Key to Maintaining a Vacuum Environment

The Importance of Vacuum Degree

The vacuum level of the cryogenic liquid oxygen storage tank is the key factor for maintaining its functionality. Once the vacuum environment is disrupted, the equipment will be unable to effectively store liquid oxygen, directly affecting the production process.

Safety Operating Procedures

To ensure the long-term stable operation of the equipment, please pay attention to:

The explosion-proof device is directly connected to the vacuum chamber through the vacuum valve.

Under the condition of stable vacuum level and without the need to replenish silica sand, it is strictly prohibited to disassemble any vacuum-related components.

The vacuum valve has undergone professional sealing treatment upon leaving the factory. Users are not allowed to disassemble it without authorization.

Professional maintenance suggestions

If you need to replenish the pearlescent powder or perform professional maintenance such as re-vacuuming, please contact our technical team. Attempting to carry out these operations yourself may result in a decline in equipment performance and increase safety risks.

Zhuoyue Gas Equipment: Your Reliable Partner

We focus on providing high-quality gas storage solutions. Through strict quality control and innovative design, we ensure that your liquid oxygen storage system is safe, efficient and economical. Contact our expert team immediately to obtain customized liquid oxygen tank solutions and optimize your gas supply process.