🟨Application Introduction

Liquid Carbon Dioxide Tanks play a pivotal role in carbonated beverage production, with their applications primarily manifested in the following aspects:

I. Raw Material Supply and Quality Control

Stable Gas Source

Liquid carbon dioxide tanks convert gaseous CO₂ into liquid form through compression and cooling processes, facilitating storage and transportation. During production, the liquid CO₂ is vaporized into gas via a vaporization system, then depressurized and injected into mixing equipment, ensuring a stable gas supply with a purity exceeding 99.99%.

Precise Control of Carbonation Level

The tanks are equipped with flow control systems that allow real-time adjustment of CO₂ injection volume. When integrated with carbonation machines, they enable precise control of dissolved CO₂ concentration, achieving the ideal balance of flavor.

II. Production Process Optimization

Efficient Mixing Technology

Liquid CO₂ is mixed with syrup and water through atomization devices. Under high-pressure conditions, the gas dissolves more effectively, forming fine bubbles that enhance the “tingling sensation” and refreshing experience of the beverage.

Extended Shelf Life

After dissolution, CO₂ forms carbonic acid (pH ≈ 3-4), which inhibits microbial growth. This extends the shelf life of carbonated beverages to 9-12 months while reducing the need for preservatives.

III. Equipment and Safety Standards

Tank Design Specifications

The inner tank is made of cryogenic steel, while the outer tank is constructed from carbon steel. The interlayer is filled with pearl sand and evacuated to ensure safe storage at temperatures between -23°C and -30°C. Compliance with national standards such as GB150-2011 “Pressure Vessels” is mandatory.

Integrated Production System

The tanks work in conjunction with isobaric fillers to maintain CO₂ pressure inside the packaging, preventing gas escape. Additionally, their antibacterial properties ensure product freshness.

IV. Economic Benefits and Environmental Sustainability

Energy Consumption Reduction

Centralized gas supply systems are over 30% more energy-efficient than dispersed cylinder supply systems, while also minimizing transportation losses.

Environmental Applications

Some companies utilize CO₂ capture technology to recover industrial waste gases, promoting resource recycling.

Through these applications, liquid carbon dioxide tanks have become a critical component in achieving efficiency, standardization, and quality assurance in carbonated beverage production.

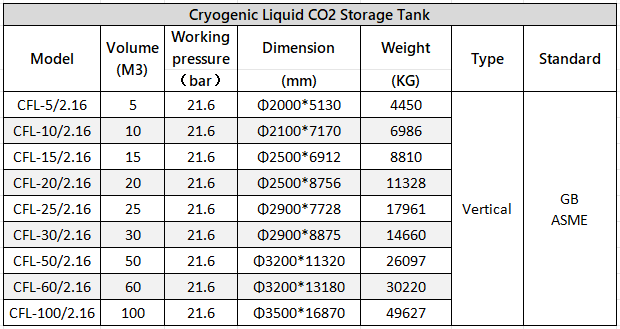

🟨Specification

🟨Company Profile

Nangong Zhuoyue Gas Equipment CO.,LTD. ,more than 20 years of production experience in the gas industry . We are specialized in ambient air vaporizer ,eletrice vaporizer ,PRMS skid and cryogenic tank . We have exported to Mexico,Turkey,Russia,Singapore, Malaysia ,Vietnam,Indonesia, Nigeria and etc. we measure our success by the success of our customers .

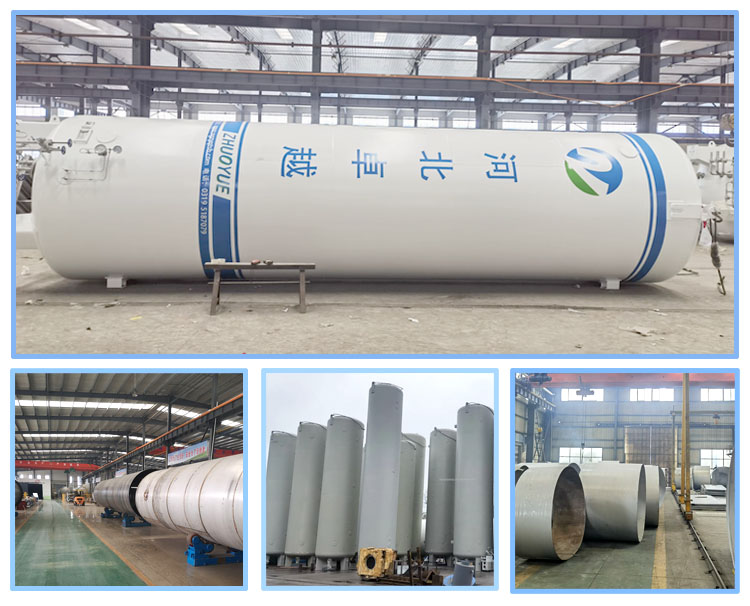

🟨Zhuoyue Gas Workshop

🟨Packing & Delivery

🟨Certifications