With the development of aquaculture towards high density and intensification, dissolved oxygen management has become the core challenge for improving yield and quality. As a high-purity oxygen supply system, liquid oxygen storage tanks are gradually becoming the industry standard through their unique physical properties and intelligent applications. This article will analyze from three dimensions: technical principles, application scenarios, and benefit advantages how liquid oxygen storage tanks provide sustainable oxygen solutions for modern aquaculture.

I. Technical Characteristics and Advantages of Liquid Oxygen Storage Tanks

1.Ultra-high purity oxygen supply

Liquid oxygen is formed by cooling oxygen to -183℃ and liquefying it, with a purity as high as 99.5%, far exceeding traditional oxygenation equipment (such as impeller oxygenators which can only increase dissolved oxygen to 5-6mg/L). It can quickly raise the dissolved oxygen concentration in water bodies to over 8mg/L, meeting the demands of high-density aquaculture.

2.Efficient storage and transportation

The density of liquid oxygen is 800 times that of gaseous oxygen, significantly increasing the oxygen storage capacity of the same volume. For instance, a 195-kilogram liquid oxygen storage tank can meet the 24-hour emergency oxygenation needs of a 5-mu pond, and through a pipeline transportation system, precise oxygen supply is achieved, reducing labor costs.

3.Environmental friendliness

The liquid oxygen vaporization process does not emit pollutants, avoiding the residue of chemical oxygenators or impurities introduced by mechanical oxygenation. It is particularly suitable for water quality-sensitive species (such as grouper and prawns).

Ii. Typical Application Scenarios in Aquaculture

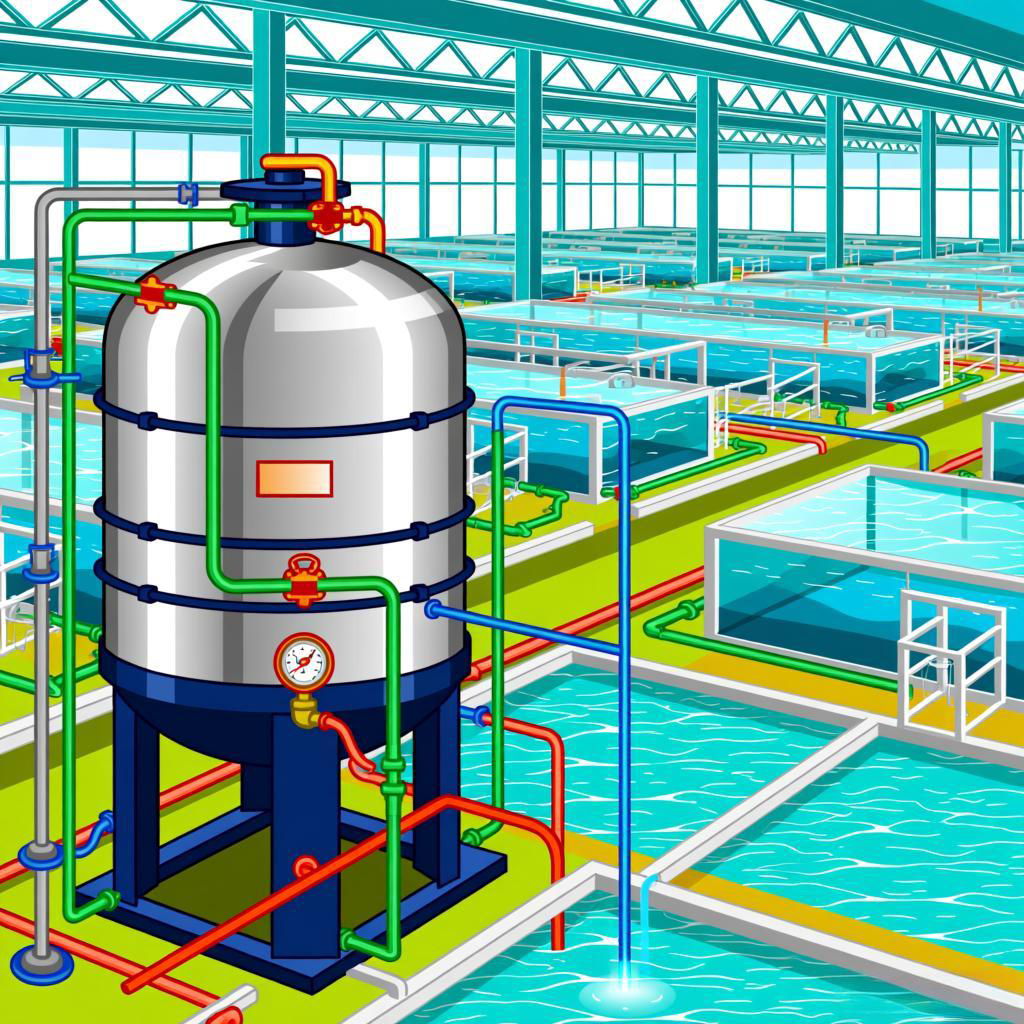

1.Factory-based recirculating water aquaculture

Applicable pool types: Cement pools, fiberglass reinforced plastic pools and other closed systems.

Case: In the breeding of high-value species such as mandarin fish and sea bass, a daily liquid oxygen dosage of 3 to 20 tons can reduce the mortality rate due to hypoxia by more than 30%.

2.Seedling cultivation stage

Young fish are sensitive to fluctuations in dissolved oxygen. Liquid oxygen is uniformly oxygenated through micro-porous aeration discs, increasing the survival rate of the seedlings by 20% to 40%.

3.Emergency oxygenation and temporary maintenance during logistics

In extreme weather conditions (such as the sweltering summer heat) or during the transportation of live fish, liquid oxygen can quickly address the issue of sudden drops in dissolved oxygen and prevent bulk losses.

Iii. Economic Benefits and Intelligent Upgrading

1.Cost-benefit analysis

Although the initial investment is relatively high, it can save 30% to 50% of electricity bills in the long term (compared with traditional aerators).

By increasing the stocking density (such as increasing production by 30% to 50%), the payback period of investment is usually 1 to 2 years.

2.Intelligent integration solution

By integrating Internet of Things (iot) sensors (such as dissolved oxygen monitors) with automatic control systems, dynamic regulation of liquid oxygen supply can be achieved. For instance, when the dissolved oxygen level drops below 4mg/L, the oxygen supply to the storage tank is automatically initiated and stops when it reaches 6mg/L, achieving precise energy conservation.

Iv. Future Trends and Choice Suggestions

1.Industry trends

With the popularization of smart aquaculture, liquid oxygen storage tanks will be deeply integrated with big data and AI technologies to form a closed-loop management of “monitoring – regulation – optimization”.

2.Selection suggestions

Small-scale farms: Modular liquid oxygen dewar flasks (with capacities ranging from 50 to 200 kilograms) can be selected.

Large-scale bases: Customized cryogenic storage tanks are recommended, equipped with remote monitoring functions.

Conclusion

Liquid oxygen storage tanks, with their features of high efficiency, environmental friendliness and intelligence, are reshaping the oxygen supply model in aquaculture. For aquaculture enterprises that pursue scale and sustainable development, investing in liquid oxygen systems is not only a technological upgrade but also a strategic choice for competitiveness.